Our zero defect strategy is key to our success. For us, delivering premium quality means leaving nothing to chance, and never compromising on excellence.

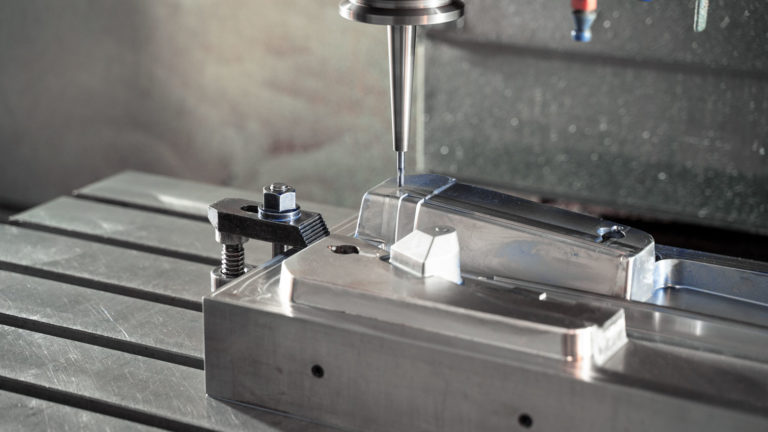

Our business is driven by our experienced workforce and continuous process improvement.

An end-to-end production and management system, based on the Toyota Production System (TPS), ensures total process visibility and smooth production flow – reflected in our high product quality.

We are constantly investing in and updating our laboratory equipment to exceed the standard required by our customer specifications. This allows us to preempt market requirements and ensure products and packaging exceed expectations all of the time.

Fogging, Flammability, Infrared / Xenon, Salt Spray, X-ray, Substance Analysis, Ageing, Melt Flow, Viscosity Bath & pH meter.

Spectral light Box, Gloss Meter, Spectrophotometer Test

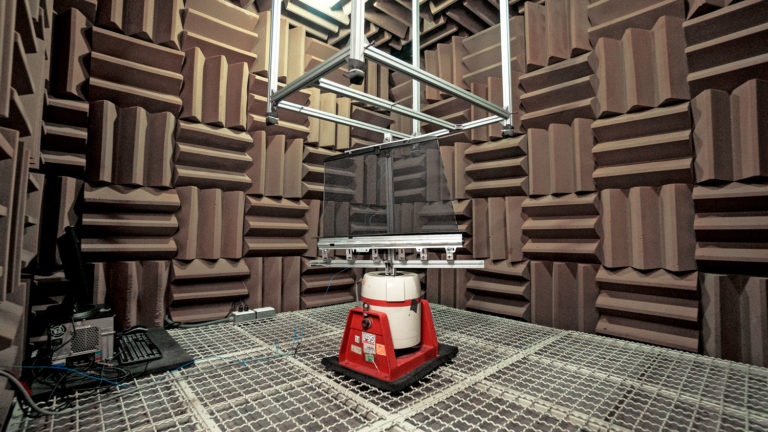

Durability in Climatic Conditions (Temperature/Humidity), Electromagnetic Vibration, Abrasion, Fatigue Shaker, Soundproofing, Universal Material Testing Machine, Low Temperature & Low Humidity Simulation Chamber.

Noise Room with Permanent Magnet Shaker from 5 to 7500 Hz

Our global footprint ensures we remain responsive to the needs of dealers and customers wherever they live and work.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |