We relish any challenge and deliver complete solutions:

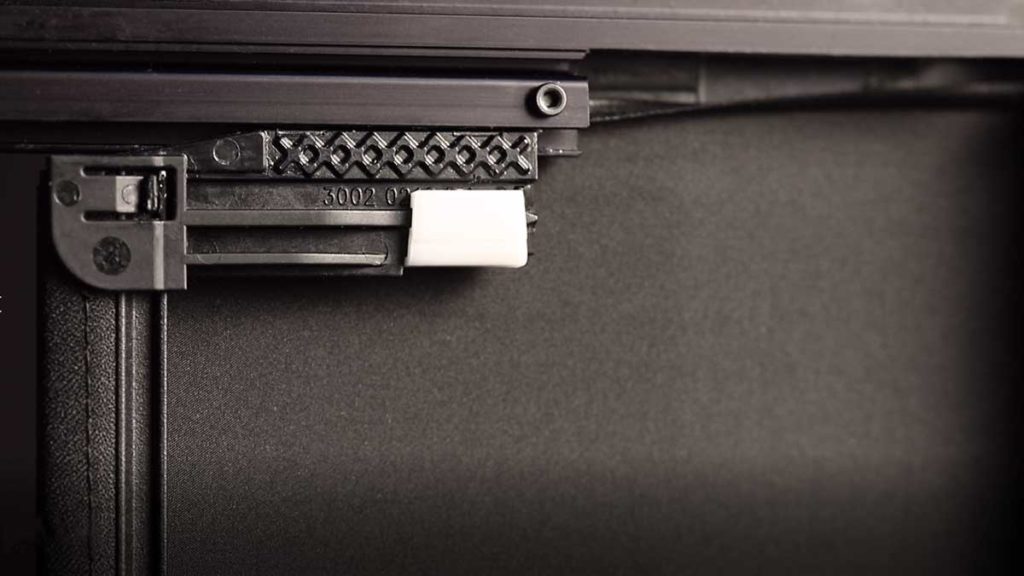

Design, prototyping, tool construction, injection-molding and stampings, material validation and finishing, and final assembly – all from a single source.

Our processes, from development through to delivery, meet the requirements of the automotive industry.

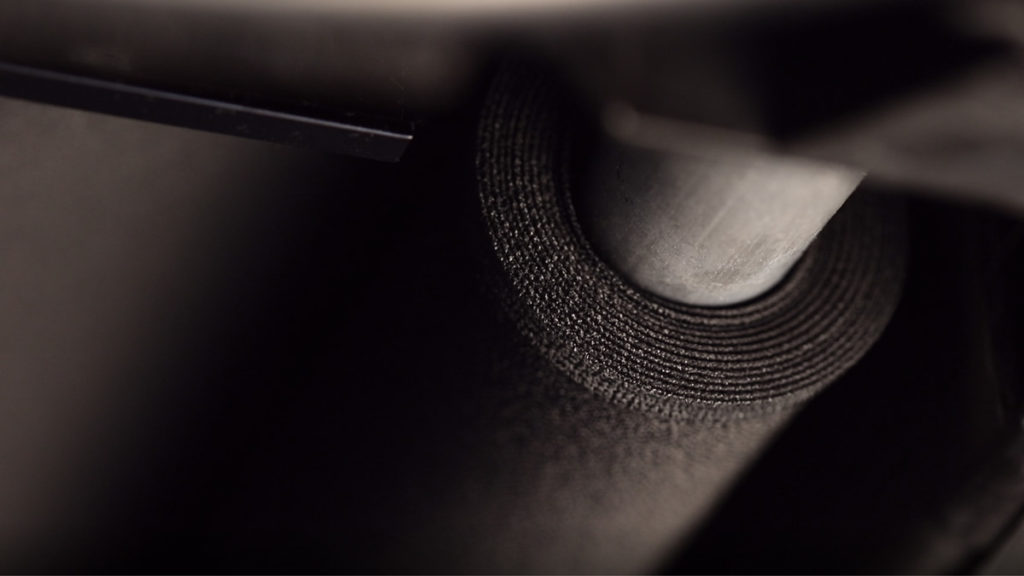

We develop shading textiles that feature the exact properties required to function & perform correctly in our sunshades. This ability gives us and our customers a competitive advantage.

Well engineered sunshade solutions require textiles that are manufactured consistently to exact specifications. Because we make our opaque multi-layer laminates in-house, we can control all the key process variables to safeguard the quality and performance of the finished sunshades.

Our customers demand components with an outstanding look and feel and functional characteristics and we are content in meeting their expectations. To this end, we have proven experience in the development and production of in-house made tooling, from injection molds to complete inspection gauges. This enables us to provide customers with expert advice and assistance in then manufacturing of our products. A ‘state of art’ toolmaking shop and our employees’ unrivalled knowledge and skill ensure we guarantee excellent products.

We develop shading textiles that feature the exact properties required to function & perform correctly in our sunshades. This ability gives us and our customers a competitive advantage. Well engineered sunshade solutions require textiles that are manufactured consistently to exact specifications. Because we make our opaque multi-layer laminates in-house, we can control all the key process variables to safeguard the quality and performance of the finished sunshades.

Our global footprint ensures we remain responsive to the needs of dealers and customers wherever they live and work.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |